By Matthew Arciuolo, C.Ped. BOC

By Matthew Arciuolo, C.Ped. BOC

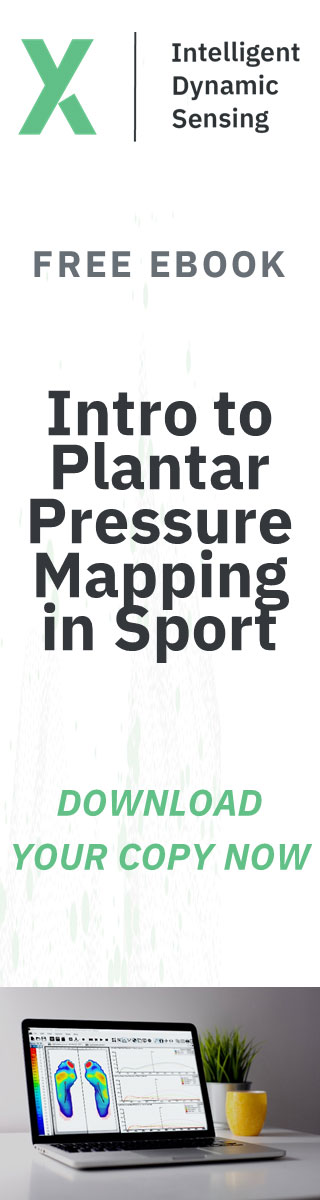

The evolution of carbon fiber plate technology has accelerated in the past few years becoming an integral part of high-end running shoes produced by many of the top brands. The Nike Vaporfly first debuted in 2017 and its popularity, along with its performance, prompted a new paradigm in running shoe technology. The Vaporfly series features a rocker-shaped carbon fiber plate embedded in the midsole (Figure 1) and it has revolutionized long-distance running – Eliud Kipchoge ran the first sub 2-hour marathon in 2019 wearing a prototype of the shoes. Since then, studies have shown that shoes with carbon fiber technology can improve run times by more than 4%.1

Run times are important in other sports besides running, something that hit home once I started working with the U.S. Olympic Bobsled Team in 2005. When I started, both the athletes and coaches said that in bobsled, where the races are measured in the thousands of a second, the difference between a Gold medal and 10th place could be determined by as little as .02 of a second. The best place to gain an advantage, they said, is at the start or the ‘push’ phase of the race – the 50m sprint prior to jumping into the sled, which contributes an average of 9.6% to the entire lapsed time of the run. As a pedorthist, I realized that carbon fiber plate technology could be used to increase the downforce that our athletes could generate in that push phase. That’s when I began to focus on how best to design what is today’s VKTRY insole, which came onto the market in 2018.

A Bit of History

Flat spring plates were first used in footwear in the early 1900’s for arch support. However, it was not until the Morton’s extension footplate, conceived by Dudley Morton, MD, came on the scene in the 1930’s that more rigid full-length insoles designed to limit the range of motion (ROM) of the 1st metatarsophalangeal (MTP) joint were used to any great extent for patients with turf toe and hallux limitus/rigidus (osteoarthritis of the big toe). These types of plates were used successfully for acute and chronic injuries to reduce forefoot and mid-foot stress while walking or running by reducing ROM and stabilizing the delicate structures of the foot. These rigid or semi-rigid plates were intended to limit the dorsiflexion ROM of the 1st MTP in order to relieve stress on the joint.

Then in 1998, Benno Nigg, PhD, and Darren Stefanyshun, PhD, researchers at the Human Performance Laboratory at the University of Calgary, studied the effects of midsole bending stiffness on jump height and joint loading. Nigg and his associates found an improvement in jump height, reduction of joint loading, and a reduction in energy loss in subjects using stiffer midsoles.2

Up until the Nike Vaporfly’s introduction, shoe insoles for athletic footwear had been passive devices, designed to attenuate shock and redistribute pressure. In whatever application, these passive insoles receive energy (force) from the user and redistribute it to areas of lower pressure. Traditional insoles are also designed to provide cushioning and support to alleviate a variety of issues such as plantar fasciitis, Achilles’ tendinitis, shin splints, and to some degree or another, align the foot, ankle, and knee into a more biomechanically advantageous position.

However, over the last 20 years, advances in materials technology have made the concept of dynamic insole technology not only possible but practical. Today’s athletes – from elite level to weekend warriors – are demanding more out of their gear, no matter what sport.

Carbon Fiber, Meet the Reverse Ellipse Spring Plate

Carbon Fiber, Meet the Reverse Ellipse Spring Plate

Carbon fiber is 5-times stronger than steel and twice as stiff. Though carbon fiber is stronger and stiffer than steel, it is lighter than steel, making it the ideal manufacturing material for a variety of products. The use of carbon fiber in footwear is a relatively new technology designed to stabilize the ultra-soft and flexible structure of high-end running shoes. Running shoes such as the Nike Vaporfly NEXT%, among others, affirmed the concept that carbon fiber could be beneficial for athletes across sports.

What sets VKTRY carbon fiber insoles (VKs) apart from standard insoles is the concept of a reverse ellipse spring plate design (Figure 2). Insoles of all types are generally made of foam, plastic or rubber and are designed to support, stabilize, and or cushion the foot. They are mainly passive devices designed to absorb the input forces generated by the human body and disperse them. The limitations of this passive concept of insoles are that the forces generated naturally by movement in any direction are not utilized efficiently and any extra required energy must come from the muscles of the lower limbs. These muscles are already handling the full weight and inertia of the athlete. The problem with traditional insoles is that the forces that the human body naturally produces – such as the force downward (load) and the force forward (momentum) – are wasted and not returned to the user. The paradigm of dynamic, rather than passive insoles is the concept behind the VKTRY technology. VKs store the energy that an athlete generates in both the forward and the downward direction, and instead of simply absorbing the energy, they store and then return that energy directly to the athlete. VKs do not add any extra energy, like a spring or motor, but rather take the energy that would ordinarily be wasted and returns it, resulting in improved performance and more explosive starts.

This increased propulsion results in increased stride length and reduced ground contact time resulting in less steps per mile and reduced fatigue. Studies at Southern Connecticut State University (SCSU) have shown an increase of an average 1.6” in the vertical jump, 4” in the broad jump and up to .4 sec faster in the 40-yard dash.3

Field research with 263 athletes at 4 Division I universities showed a 41% reduction in toe injuries and a 22% reduction in lower leg injuries compared to the 3 years prior.4

Independent clinical research from the Korey Stringer Institute at the University of Connecticut led by Douglas Casa, PhD, found that VKTRY insoles provided significantly greater stabilization of the knee, ankle, and foot – all factors that lead to a lower risk of lower leg injury. 4 The athletes using VKs also showed reduced joint loading upon landing.

VKTRY insoles are designed with carbon fiber to store, focus, and release the energy generated by the human body during normal walking, running, or jumping movements. This force, which would normally be distributed among the 3 planes of motion, is focused saggitally – directing force downward – in the plane most beneficial to the athlete in line with Newton’s third law of motion: for every action in nature there is an equal and opposite reaction). Or, more technically: FA = −FB – wherein one object (A) exerts a force (FA) on a second object (B), then B simultaneously exerts a force (FB) on A, and the 2 forces are equal in magnitude and opposite in direction: FA = −FB.

VKTRY insoles are designed with carbon fiber to store, focus, and release the energy generated by the human body during normal walking, running, or jumping movements. This force, which would normally be distributed among the 3 planes of motion, is focused saggitally – directing force downward – in the plane most beneficial to the athlete in line with Newton’s third law of motion: for every action in nature there is an equal and opposite reaction). Or, more technically: FA = −FB – wherein one object (A) exerts a force (FA) on a second object (B), then B simultaneously exerts a force (FB) on A, and the 2 forces are equal in magnitude and opposite in direction: FA = −FB.

VKs return an “impulse” to the user, called a “moment” in biomechanics. The magnitude of this is difficult to define because there are many factors that contribute to that measurement, such as tendon/ligament integrity, muscle fast/slow twitch composition as well as technique, which can all skew the data. This moment is similar to one frame in a video…essentially a snapshot in time. As a result of storing potential energy and releasing kinetic energy at the metatarsals and consequently at the ankle mortise, VKs increase the rate, force, and amount of plantarflexion.

Regarding performance, research at SCSU Human Performance Laboratory showed an average of 9.3% increase in rate of force development (explosiveness) and an 8.1% increase in ground force (GRF).3

VKTRY offers 5 different Pro Levels, essentially flexibility levels, determined by our proprietary algorithm and based on the user’s weight, shoe size, sport, age, and gender. A 300lb offensive lineman with a size 15 foot is going to need a stiffer Pro Level than a 100 lb. tennis player with a size 6 foot. This Pro Level system assures the user, no matter what size, the proper VK for optimal performance.

Design Specifics: How It Works

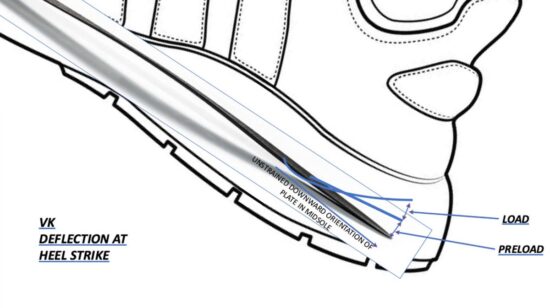

One of the VK’s most important design features is its reverse ellipse configuration. The leaf spring concept has been used for over a century because it is not only efficient in absorbing – but also returning energy. However, when that ellipse is inverted, as in the VK design, instead of the load points being at both ends, the load point is in the center of the beam with the posterior and distal aspects of the plate absorbing the energy.

Unlike a leaf spring however, the reverse ellipse design is not only acted upon by a load saggitally, but also the spring is deformed at the metatarsals during dorsiflexion. This combination of deflection at the center of the plate along with deflection at the metatarsals provides a significant amount of potential energy storage and transitively an increase in kinetic energy return.

Anatomically, the human foot has an acceptable ROM at the metatarsals of -30° (plantarflexion) to +80° (dorsiflexion) after which point the muscles, tendons, and ligaments are placed at a mechanical disadvantage to efficiently move the joint. It is at this point when the foot is most vulnerable to injury. These values are largely dependent on many factors such as ligament and tendon integrity, posterior chain strength/flexibility, and others including plantar fascia and spring ligament attachments.

The available range of 1st MTP joint dorsiflexion largely depends on the position of the 1st ray, but as we approach the limits of acceptable ROM, the joints are placed at a mechanical disadvantage.

The available range of 1st MTP joint dorsiflexion largely depends on the position of the 1st ray, but as we approach the limits of acceptable ROM, the joints are placed at a mechanical disadvantage.

Let’s take for example an individual whose foot is dorsiflexing to 30 degrees while running (Figure 1). When the joint is bent to 30 degrees, a flat plate is strained to 30 degrees, thereby storing 30 degrees of potential energy.

In current running shoes using carbon fiber tech, the carbon plates are rocker-shaped and assume a 10-degree upward rocker at the toe. When the 1st MTP is dorsiflexed to 30 degrees, the plate is only strained to 20° and therefore can only store that much energy (Figure 2).

The VKTRY insole design places the foot on a plane whereby the 1st MTP is superior to the Hallux unweighted, therefore it’s ROM starts, not at 0° but at -10°. This gives the 1st MTP a mechanical advantage in that the VK is already storing 10° of potential energy when the 1st MTP is at 0 compared to a flat plane insole, which cannot store energy if is not strained.

With the VK’s unique contour, when the 1st MTP is at a dorsiflexed angle of 30 degrees, the VK is strained to 40° as a result of its slope, storing an extra 10 degrees of potential energy before the 1st met has even begun its travel (Figure 3).

In engineering, material deflection is the degree to which a structural element is displaced under a load and the materials response to this load. The deflection distance of a member under a load can be calculated by integrating the function that mathematically describes the slope of the deflected shape of the member under that load. In the case of the above example, the slope of the flat plane is 0° whereas the slope of the VK is 10° and the slope of the rocker plate is -10°.

A flat plate is an example of a homogenous beam deflecting at the same rate at any point, depending on the location of the load and its supports. Because of the Pro Level (tiered) design of the VK, the deflection (f) is non-homogenous, meaning that the deflection at the metatarsals is always less than the deflection angle distally because as the layers of carbon fiber decrease distally, deflection will be greater mirroring the MTP, IP, and DIP joints. In all Pro Levels, the VK has the most layers directly inferior and posterior to the metatarsal heads and as it proceeds distally, the layers decrease in a step-down fashion thus becoming more flexible distally. The VK’s slope is not constant but rather a non-linear deflection. This distinction is important in that the human foot is not a linear, rigid structure. VKs are designed to biomechanically compliment the structure of the foot by employing these varying Pro Levels in its design; stronger where the foot is stronger, and more forgiving where the foot is more delicate.

Conversely, the very characteristics that make the VK an effective lever for the foot during propulsion also serve to decelerate the athlete upon landing. Because VKs afford extra degrees of dorsiflexion energy storage, they also give the athlete an extra measure of deflection upon landing at the heel and toe, similar to landing on a diving board. This added ROM of plate deflection during concentric movements also allows efficient and softer deceleration upon landing.

The march of technology, in virtually any field cannot be stopped, especially when the results are a benefit to the end user of the technology. VKTRY Performance Insole technology represents a quantum leap in that inevitable progress.

- Muniz-Pardos B, Sutehall S, Angeloudis K et al. Recent improvements in marathon run times are likely technological, not physiological. Sports Med. 2021;51:371–378. doi.org/10.1007/s40279-020-01420-7

- Nigg BM, Kahn A, Fisher V, Stefanyshyn D. Effect of shoe insert construction on foot and leg movement. Med. Sci. Sports Exerc. 1998;30:550-555.

- Athletic Performance Research Results Summary. September 2020. Available at https://cdn.shopify.com/s/files/1/0072/5568/7283/t/105/assets/VKTRY_Athletic_Performance_Research_Results_-_Sept_2020.pdf?v=62306910182799556791654011585 Accessed Aug. 1, 2022.

- Casa D. VKTRY Injury Protection Research Results – May 2020. Available at https://cdn.shopify.com/s/files/1/0072/5568/7283/files/VKTRY_Injury_Protection_Research_Results.pdf?v=1594404910. Accessed Aug. 1, 2022.