Engineers from the University of Glasgow Bendable Electronics and Sensing Technologies (BEST) group have developed a new method for manufacturing electronics, which prints high-performance silicon directly onto flexible materials. This work could lead to breakthroughs in technologies including prostheses.

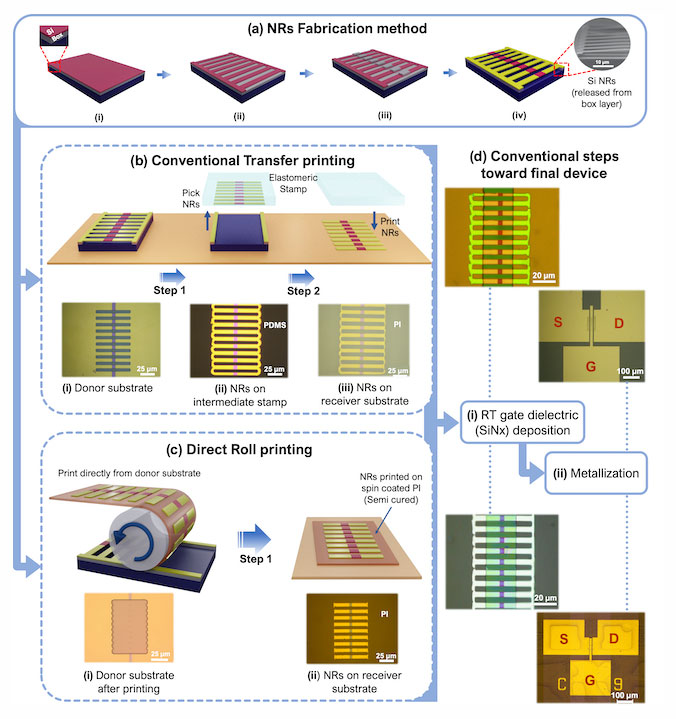

Until now, the most advanced flexible electronics have been mainly manufactured by transfer printing, a 3-stage stamping process a bit like receiving an ink stamp in a passport. However, the process has limitations, including precisely controlling variables like the speed of transfer, and the adhesion and orientation of the nanostructure, making it difficult to ensure each stamp is identical.

The Glasgow team’s approach removes the second stage. Instead of transferring nanostructures to a soft polymeric stamp before it is transferred to the final substrate, their new process—“direct roll transfer”—prints silicon directly onto a flexible surface. The process begins with the fabrication of a thin silicon nanostructure of less than 100 nanometers. Then the receiving substrate—a flexible, high-performance plastic foil material called polyimide—is covered in an ultrathin layer of chemicals to improve adhesion. The prepared substrate is wrapped around a metal tube, and a computer-controlled machine developed by the team then rolls the tube over the silicon wafer, transferring it to the flexible material. The team has managed to create highly uniform prints over an area of about 10 square centimeters, with around 95% transfer yield.

“Layers of flexible material stretched over prosthetic limbs could provide amputees with better control over their prosthetics, or even integrate sensors to give users a sense of ‘touch,’” said Ravinder Dahiya, PhD, the leader of the BEST group at the University of Glasgow’s James Watt School of Engineering. Moreover, the process is simpler; capable of producing high-performance flexible electronics with results as good as, if not better, than conventional silicon-based electronics; and potentially less expensive and more resource-efficient, he added.