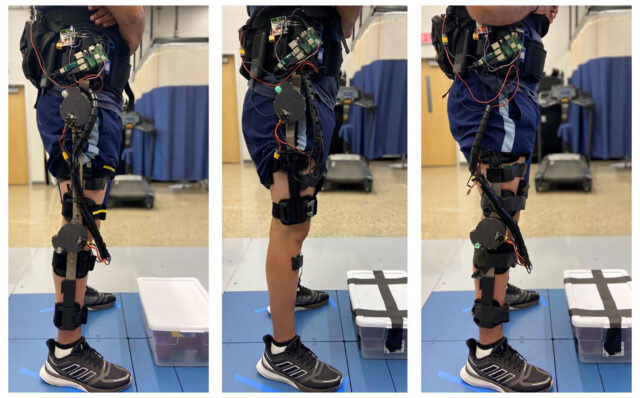

Preliminary knee and hip designs for a new powered exoskeleton system. It attaches motors to off-the-shelf orthotic braces to provide better mobility to the wearer. Image courtesy of Locomotor Control Systems Laboratory.

In an effort to bring robotic assistance to workers, the elderly, and more, a University of Michigan (U-M) team is developing a new type of powered exoskeleton for lower limbs, funded by $1.7 million from the National Institutes of Health. The team plans to develop a modular, powered exoskeleton system that could be used on 1 or multiple joints of the legs.

Much like adding a small motor to a bicycle to provide the rider with added assistance while pedaling, “we can take the conventional ankle, hip, or knee braces used today, add a self-contained specialized motor and gear system, and provide power at a specific joint to increase mobility,” said Robert Gregg, PhD, associate professor of electrical and computer engineering.

Conventional orthotic braces cannot actively assist human joints during challenging activities. Exoskeletons are built so that it is difficult for users to move against the motor, or backdriving, partly because they are usually designed to replace the complete function of an entire limb. Partially assisting specific joints is a different challenge. A great hurdle for exoskeletons is that they must accurately recognize the user’s intent and match that intent with a correct action. Otherwise, the exoskeleton adds to the effort required from the user.

There are 2 keys Gregg and his team envision will make up for these shortcomings: a newer style of motor and transmission and a different kind of control algorithm. Gregg’s team will use a flat, pancake-style motor that was originally used in drones. These motors don’t need as many gears to deliver enough torque to help power a human, which makes them easy to backdrive. To control the motor and transmission, the team will develop a “task-invariant” control algorithm, which will not rely on knowing the task the user is trying to complete in order to effectively provide assistance. Instead of predicting where a human will move, the team will simplify the problem and work on altering how the human moves.

“With this method, we may compensate for gravity: No matter where you move, the motor can assist with that. Another example is inertia: No matter where you move, the motor can compensate for limb inertia to make movement easier,” Gregg said.

The team will determine the best configurations of the modular system for different populations. The team will also study whether the additional weight of the motor is helpful overall.